Auto Pour

A non-disruptive pyrometer system designed specifically to measure the temperature of liquid metals in the foundry, during the process of pouring into moulds and castings.

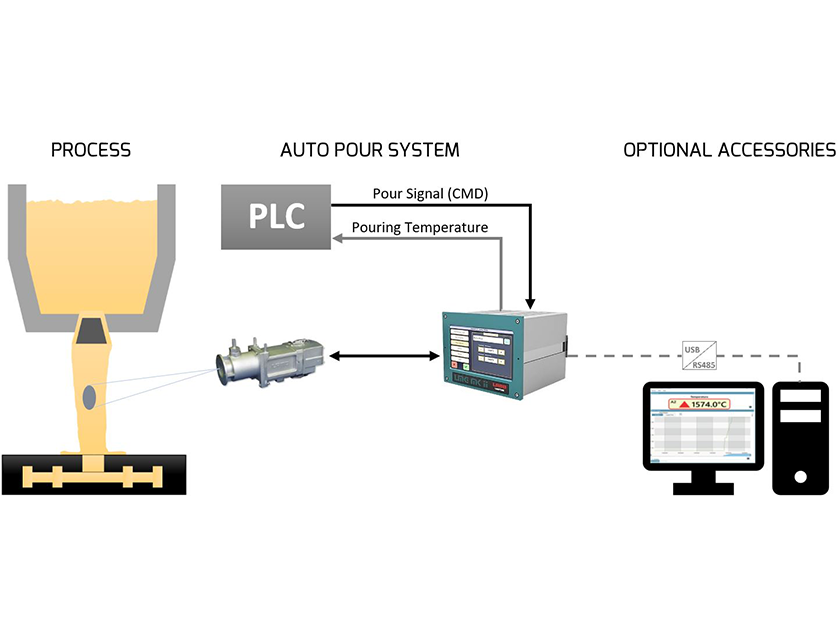

The application-specific Auto Pour Pyrometer System is designed to provide accurate liquid metal temperature readings in the liquid stream, the most direct measurement location.

Using a non-contact measurement that does not interrupt the casting process, Auto Pour delivers one accurate, repeatable value, measured and calculated for each pouring. This data helps reduce operating costs while improving casting quality.

The system detects the start and end of the pouring process, monitoring and outputting these readings for further analysis and storage.

A product of AMETEK Land’s continued innovation in precision temperature measurements, the Auto Pour Pyrometer System is specifically designed to support automated processes in the foundry industry.

A PROVEN MEASUREMENT

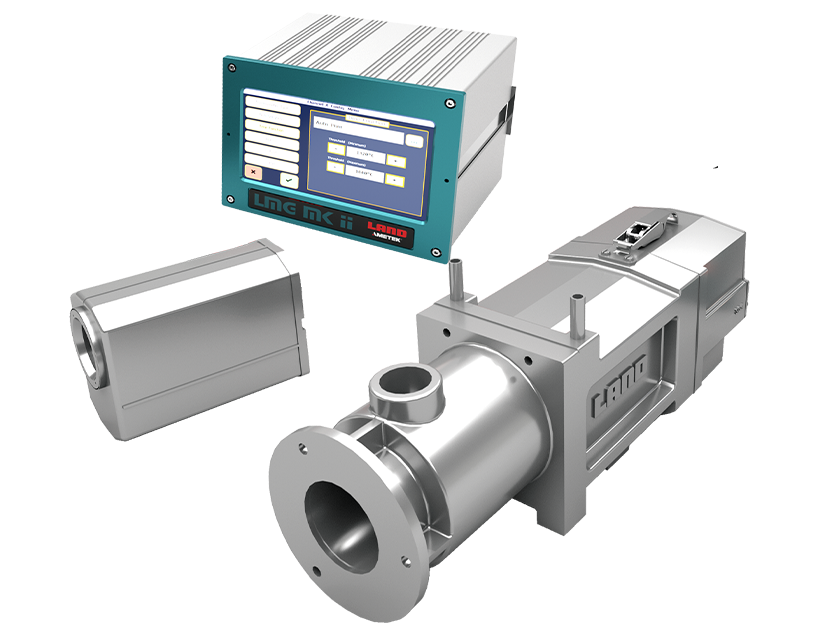

The Auto Pour system uses a high precision, spot application pyrometer and operates at a wavelength selected to ensure minimal errors from variable emissivity and atmospheric absorption and provides pouring stream tracking with a special field of view.

IMPROVED ACCURACY

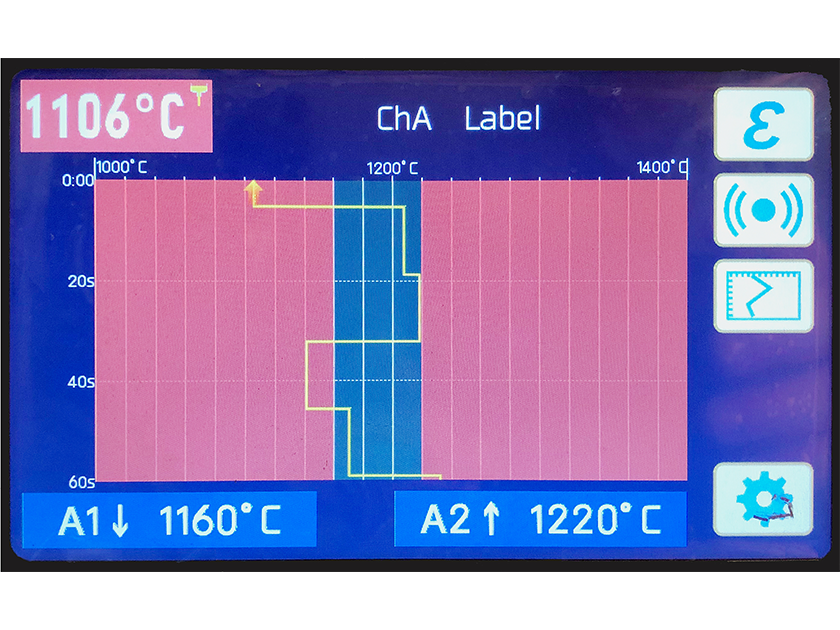

The multi-function Landmark Graphic MkII (Auto Pour) signal processor uses a graphical display for improved measurement accuracy, usability and multiple interface.

The pyrometer is protected against the harsh foundry conditions by an air/water cooling jacket. This also contains an air purge unit for maintaining a clean lens and window during operation.

Brochures