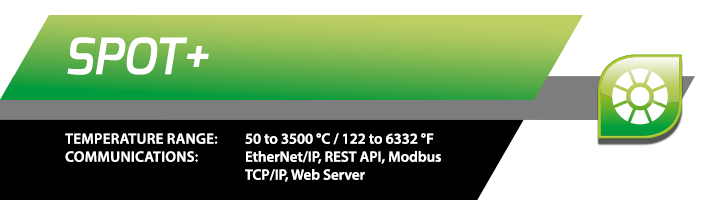

SPOT+

The SPOT+ range of smart infrared pyrometers bring high precision, advanced IIoT connectivity and visible light process video to the AMETEK Land SPOT family.

Combining EtherNet/IP, REST API, web server, Modbus TCP, image streaming, analogue and alarm outputs within one device, SPOT+ makes non-contact temperature measurement accurate, flexible and easy to use.

Pyrometer readings and configuration settings are available on the rear display and remotely via a web browser or through software. Standard body models offer motorized focus for remote control with focus-assist flashing green LED (Patent GB2497609) and visible light process video to confirm focal sharpness, measurement spot size and location. Fiber-optic variants use a red LED for alignment.

Flexible design with adapters provide simplified installation and easy replacement of older pyrometers. SPOT+ is designed to be interchangeable with existing fixed spot pyrometers.

AMETEK Land IMAGEPro software can be used to configure, display and log data and process images from multiple SPOT+ pyrometers, or a combination of AMETEK Land thermal imagers and SPOT+ pyrometers. Advanced software functionality allows SPOT+ measurements to be used for live background temperature, emissivity or dirty-window compensation of imaging systems.

Alternatively AMETEK Land SPOTPro software provides datalogging at up to 1 kHz data rate and control of the SPOT+ pyrometers when used with the SPOT Actuator.

To ensure security with multiple users, various levels of access are available in both SPOTPro and IMAGEPro software. Data log frequency, file size, save and archive locations are all configurable. AMETEK Land software is the perfect choice for smaller operations where traditional process control systems may be absent.

INDUSTRIAL INTERNET OF THINGS

SPOT+ has been designed to support multiple communication interfaces and is ideal for connection to Industrial Internet of Things (IIoT). It supports the popular EtherNet/IP (Industrial EtherNet) and REST API protocols as well as Modbus TCP/IP. Its built-in Web Server interface allows SPOT+ to communicate with any web browser for configuration and diagnostics. Password protection and internal encryption enables safe remote process monitoring.

Traditional analogue connections are supported via two 4-20 mA outputs, one 4-20 mA input, relay output and contact closure CMD input.

THE STAND-ALONE SOLUTION

Everything you need is built into SPOT+ pyrometers: with no separate processor required, set-up and operation is simple. Intuitive local and remote interfaces manages operational and sophisticated processing functions, while digital and analogue communications and alarm contacts are all included as standard.

Patented Bright Green, easy to see pulsed LED sighting pattern ensures optimum focus while exactly confirming the target spot's location and size. Optics feature a motorised focus that can be easily accessed locally at the pyrometer or remotely over an EtherNet link.

FASTER, MORE ACCURATE MEASUREMENTS

The SPOT+ rapid response times and smart onboard processing provide immediate live process control SPOT+ gives you accurate, stable measurements more quickly – reducing maintenance time and enabling faster process adjustments.

A PRECISE FIT FOR YOUR APPLICATION

Every customer application is different, so the SPOT+ product range is designed to match specific process challenges. Through extensive hardware, software, accessory and remote sensing options, SPOT+ partners your needs precisely.

AMETEK Land SPOT+ Pyrometers are available in a range of models. Adapted for temperature measurements ranging from 50 to 3500 °C, the extensive SPOT+ range also meets the individual process challenges for industries including Power Generation, Aluminium, Steel and Industrial Processing.