SPOT MM - Liquid Metal and Tapping

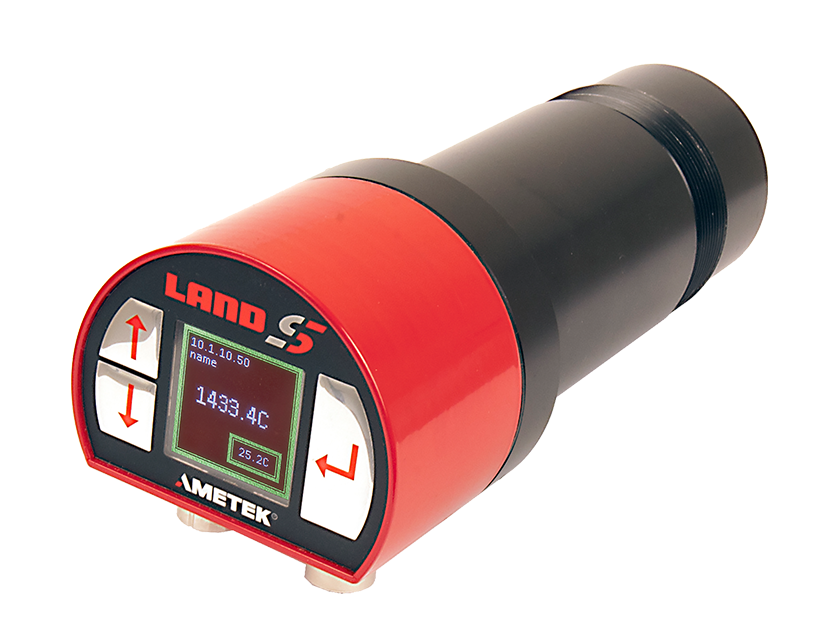

An advanced non-contact infrared spot pyrometer specifically designed for liquid metal temperature measurements in foundry and tapping applications.

The smart SPOT MM (MeltMaster) application pyrometer provides a single-sensor solution for liquid metal temperature measurements in foundry and tapping applications.

Optimised signal processing and a dedicated application mode allow the SPOT MM to accurately measure tapping stream temperatures independent of surface and condition changes during the process.

The SPOT MM has millisecond responsivity with integrated time functions to monitor and hold the tapping temperature for a configured time or until the next tapping process starts.

Multiple digital and analog interfaces enable easy integration into new and existing process control systems. An internal visual camera aids alignment and provides a remote process view via the integrated webserver of the SPOT MM. The webserver and Modbus TCP/IP enable full remote access to the pyrometer without the need for any additional software.

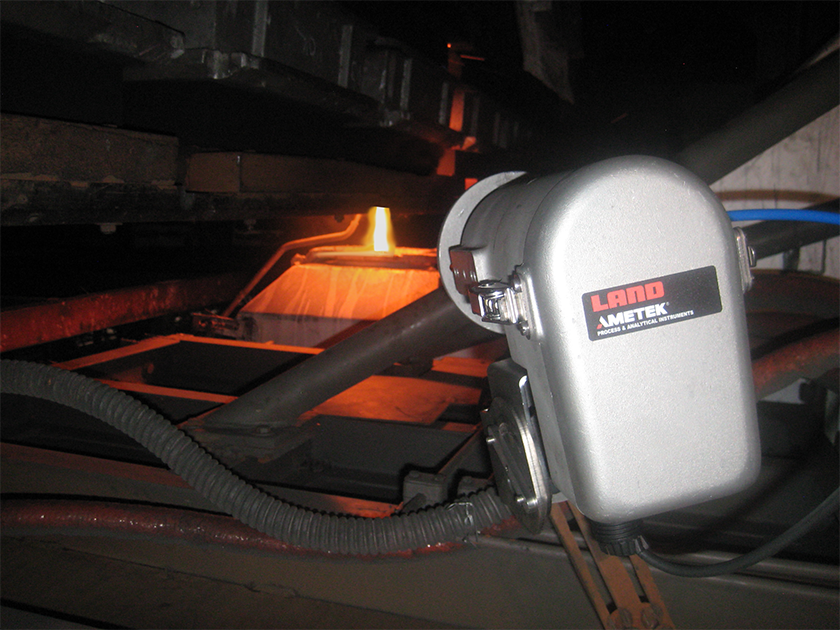

The SPOT MM is compatible with the SPOT Actuator for alignment with moving or multiple tapping streams. A further range of accessories, including the industrial enclosure with cooling and air purging options, allow the SPOT MM to work in harsh environmental conditions 24/7.

FUNCTIONALITY

In foundry tapping applications, pouring stream conditions are typically not stable. As the liquid metal surface changes during the pouring process, and an initial thin variable oxide layer is established, a special pyrometer is needed to accurately measure the liquid metal temperature and obtain the most accurate and continuous readings.

Optimised signal processing and the integrated application mode allows the SPOT MM to accurately measure tapping stream temperatures without the influence of surface and condition changes during the process. Multiple digital and analog interfaces allow the SPOT MM easily to monitor the actual temperature and being integrated into new and existing process control systems. The integrated visual camera enables the operator to monitor and control the tapping process, while the integrated webserver of the SPOT MM enables a full remote access of the pyrometer without the need of any additional software.

Autonomous Operation - Continuous measurement without the need for operator adjustments

Fast Tapping Stream Temperature Measurements - Accurate temperature measurement up to 1000 times per second

Plug’n’Play - operation with options for reference temperature calibration

Automatic Alignment - The SPOT Actuator quickly adjusts to the tapping stream position

Integrated Video Camera - Easy adjustment of the measurement point and remote image of the measured stream

Multiple Interfaces - Analog and digital in and outputs, Modbus/TCP Ethernet protocol

Software - Integrated webserver and optional SpotPro software allow data to be accessed and displayed remotely

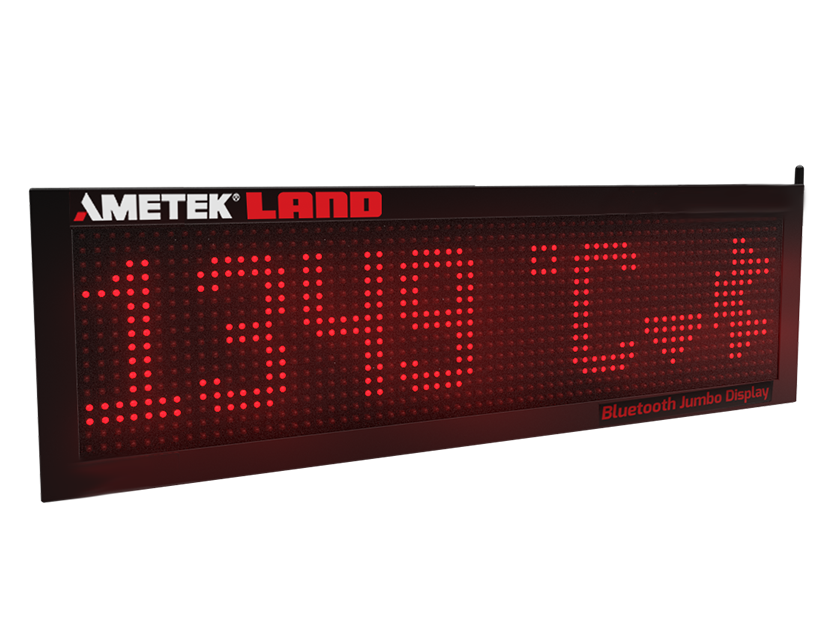

Jumbo Display - Optional remote display allows measured temperature to be seen at a distance

The SPOT MM is designed to be interchangeable with existing fixed spot pyrometers. To view the full range of mountings and accessories available, see our SPOT Mountings and Accessories brochure.

For specific recommendations on the choice of mountings, brackets, cables or any other accessories that may suit your specific industry or installation, please contact an AMETEK Land sales manager or representative for further advice before ordering.